Product details

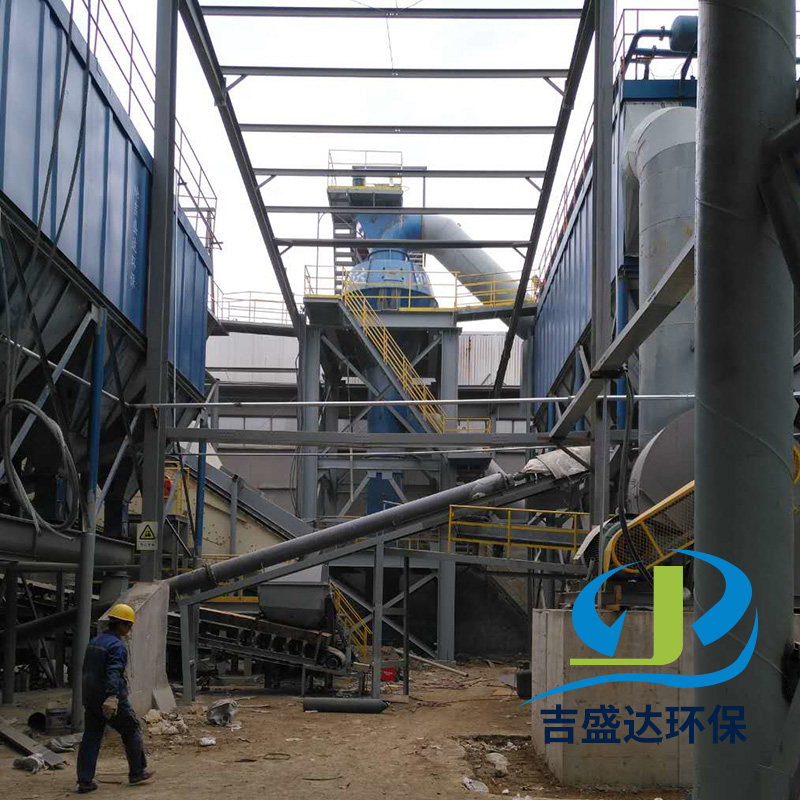

Product overview

In cement industry production, in order to improve the efficiency of the grinding system and reduce the energy consumption of products, the circular flow grinding system is widely used. As an important part of the system, the performance of the powder separator is advanced or not directly affects the efficiency of the system. Therefore, the research and development of powder selecting machine has been paid attention to by various scientific research institutes and industrial and mining enterprises.

Series of high-efficiency anti-condensation combined form double rotor powder separator is the latest type of powder separator developed by the technicians of Yancheng Jishengda Environmental protection Engineering Co., LTD., combining with foreign advanced powder separator technology and applying plane eddy current theory to the whirlwind powder separator. It has been proved that the efficiency of selecting powder can reach 85-90%, and the fineness adjustment is convenient and flexible, and the performance is stable and reliable.

Structure performance

Compared with traditional powder separator, JSM series high efficiency anti-condensation combined double rotor powder separator has the following unique advantages:

1, the use of removable combined propeller spreading plate. It not only has the effect of spreading material, but also produces the updraft to make the material particles boiling on the surface of the spreading material disk is dispersed, which can increase the classification and dispersion performance of the material particles.

2. Advanced classification principle. Combined with a variety of powder selecting machine theory, the use of centrifugal force in the opposite direction and the balance of the flow to the heart suction, the material through the classification interface is clear and the powder selection area, so the classification accuracy is high.

Working principle:

1, the final by the classifier upper hopper into the classifier inner shell, fall into an organic whole with rotor material plate, the combination of propeller in materials plate under the action of high speed rotation of round out, at the same time by the effects of the rising air propeller blade and materials plate lifted upward, materials formed on rotating propeller blade in boiling. The finer particles in the material float up in a suspended state, while the coarser or heavier materials are dispersed by the blade of the spreader tray and fall down along the wall of the cylinder to complete the initial powder selection.

2. The lower cage rotor is provided with the lower cage rotor 10. The lower cage rotor rotates with the main shaft to form an eddy current, which will break the heavy material falling along the wall of the cylinder again.

6. In the powder selection room, the air flow near the surface area of the rotor classification ring and the materials scattered in the air flow are driven by the classification ring and the classification ring together to do high-speed rotation, in the classification ring together with high-speed thunder, forming a uniform strong vortex air flow around the classification ring. In this area, the relationship between centrifugal force and suction force is constant at any position. The centrifugal force received by materials in the airflow can be adjusted by adjusting the speed of motor 2 spindle 3. When the speed increases, the force also increases, at this time if the air volume is constant, the cutting particle size decreases, the product becomes fine; If the speed is reduced, the product becomes coarse.

4. After classification by the upper cage rotor, fine particles enter the external cyclone dust collector with the circulating wind. As a result of the new design of the cyclone dust collector air inlet with a guide plate, the inner cone added a reflection screen, the lower end of the reduction plate, so that the cyclone dust collector fluid resistance decreased significantly. Under the action of the wind guide plate, the circulating air enters the cyclone dust collector with high wind speed. When the snail Angle expands, the wind speed decreases suddenly, which accelerates the particle settling and improves the dust collecting efficiency of the cyclone dust collector.

Yancheng Jishengda Environmental protection Engineering Co., Ltd. has long been committed to the production and development of energy-saving and environmental protection equipment in the building materials industry. It is a manufacturer specializing in the production and sales of building materials machinery and energy-saving and environmental protection equipment in China. Adhering to technological innovation, the company has formed three pillar industries of environmental protection equipment and environmental protection engineering technology, powder selection equipment and grinding technology, drying equipment and drying engineering technology. Now we have more than 20 property rights patents: rotary kiln professional bag dust collector, large line spraying pulse long bag dust collector, efficient eddy current separator, coal mill dynamic separator, efficient double rotor separator, three cylinder dryer, circulation reciprocating multi-cylinder dryer and so on. Service Hotline:139-6208-6422